Platos

Hojas

Barras Circulares

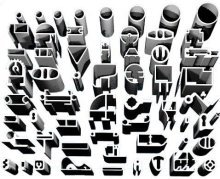

Tubos / Extrusion / Perfil

1050

ASTM B209 / Al99.5 / 1050 / H24

| Chemical Properties | % Value |

| Silicon (Si) | 0,5 - 0,25 |

| Manganese (Mn) | 0,00 - 0,05 |

| Magnesium (Mg) | 0,00 - 0,05 |

| Copper (Cu) | 0,00 - 0,05 |

| Titanium (Ti) | 0,00 - 0,03 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,05 |

| Aluminium (Al) | 99,2 - 99,9 |

| Physical Properties | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 640 °C |

| Thermal Expansion | 21.8 µm/m.°C |

| Modulus of Elasticity | 68 GPa |

| Thermal Conductivity | 230 W/m.K |

| Electrical Resistivity | %61 IACS |

| Mechanical Properties | Value |

| Proof Strength | 63 MPa |

| Yield Strength | 110 MPa |

| Shear Strength | 84 MPa |

| Elongation A50 mm | 6.8 % |

| Hardness | 45 HB |

The 1050 H24 aluminum alloy is known for its excellent machinability, lightweight nature, and good corrosion resistance. As one of the purest forms of aluminum, it is commonly used in applications requiring lightweight structural components. The cold-worked H24 temper provides medium hardness, making it suitable for applications that require durability without excessive flexibility. This alloy also offers good electrical and thermal conductivity, which makes it widely used in electrical equipment and heat-sensitive components.

The 1050 H24 alloy is highly suitable for anodizing. Anodizing forms a protective and aesthetically pleasing oxide layer on the surface, enhancing corrosion resistance and providing an attractive finish. This makes it ideal for decorative and durable surface applications. In terms of weldability, it performs well as the alloy is a relatively pure form of aluminum, which makes welding easier and allows for strong and reliable welds when the proper welding techniques are applied.

In terms of bending and forming, the 1050 H24 alloy is highly versatile due to its excellent machinability. It performs well in shaping and bending processes, making it ideal for use in automotive, construction, and packaging industries. However, its use in high-vibration environments is limited. As a relatively low-strength alloy, it is not suitable for applications that require resistance to high stress or vibrations.

Regarding corrosion resistance, the 1050 H24 aluminum alloy is highly resistant to atmospheric conditions, water, and moisture. Its pure aluminum content ensures durability in a variety of environments. However, due to its relatively low strength, it is not suitable for heavy-load applications or environments with high temperatures. The advantages of 1050 H24 include excellent machinability, anodizing compatibility, and corrosion resistance, while its drawbacks include low strength and limited performance under high temperatures.

Choosing Factors for 1050 H24

- Strength: Average

- Machining: Weak

- Weldability: Excellent

- Formability: Okay

- Corrosion Resistance: Excellent

- Heat Treating: Yes

Some Well-Known Applications for 1050 H24

As equipment material in the chemical industry,

In road signs,

And also it is used in kitchen appliances.

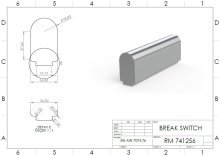

- Plate

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 0.4 up to & incl. 0.8 | 370 MPa | 430 MPa | %6 |

| Over 0.8 up to & incl. 1.6 | 380 MPa | 440 MPa | %7 |

| Over 1,6 up to & incl. 6,0 | 390 MPa | 440 MPa | %7 |

Calculador de Peso

Calculador de Peso