Cold Drawn Round Bar

Cold Drawn Tube

2024

Cold Drawn/Finished (CF) / AlCu4Mg1 (Soğuk Çekim) / 2024 / T4

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,50 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,30 - 0,90 |

| Magnesium (Mg) | 1,20 - 1,80 |

| Copper (Cu) | 3,80 - 4,90 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.78 g/cm³ |

| Melting Point | 502 °C |

| Thermal Expansion | 22.9 µm/m.°C |

| Modulus of Elasticity | 73.1 GPa |

| Thermal Conductivity | 121 W/m.K |

| Electrical Resistivity | 30% IACS |

| Mechanical Properties | Value |

| Proof Strength | 324 MPa |

| Yield Strength | 469 MPa |

| Shear Strength | 283 MPa |

| Elongation A50 mm | 16% |

| Hardness | 120 HB |

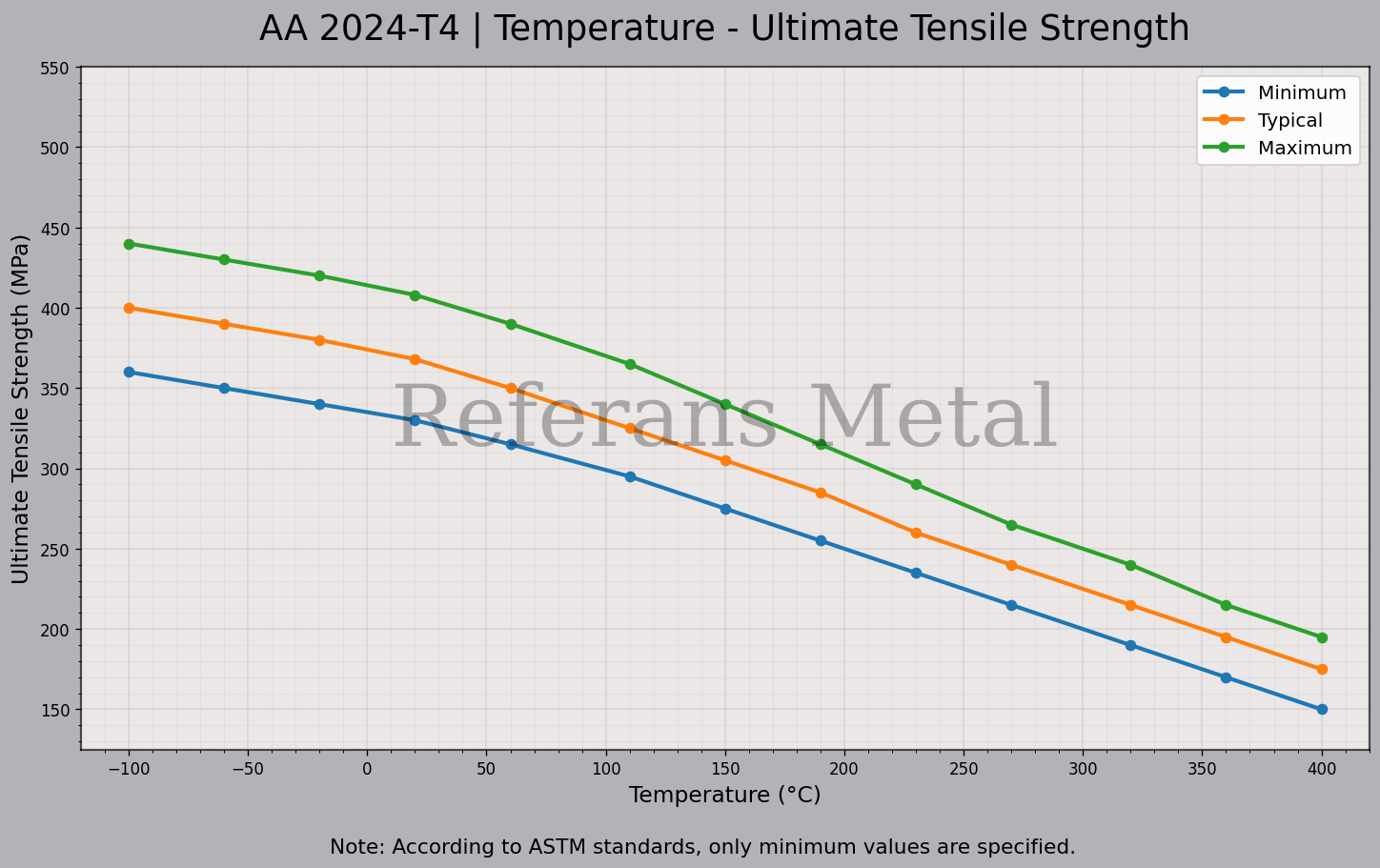

| 2024 T4 Temperature – Ultimate Tensile Strength Graph |

|

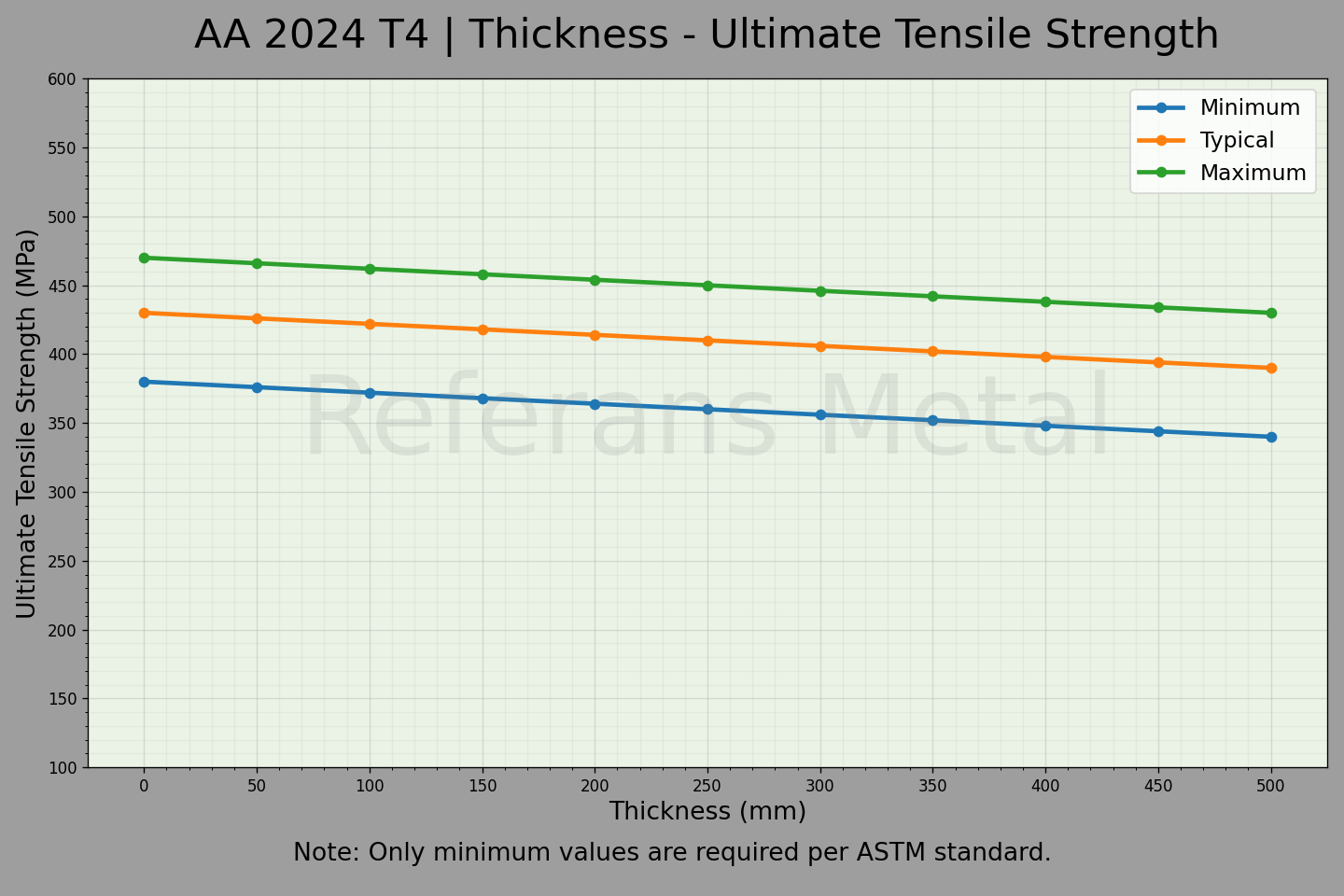

| 2024 T4 Thickness – Ultimate Tensile Strength Graph |

|

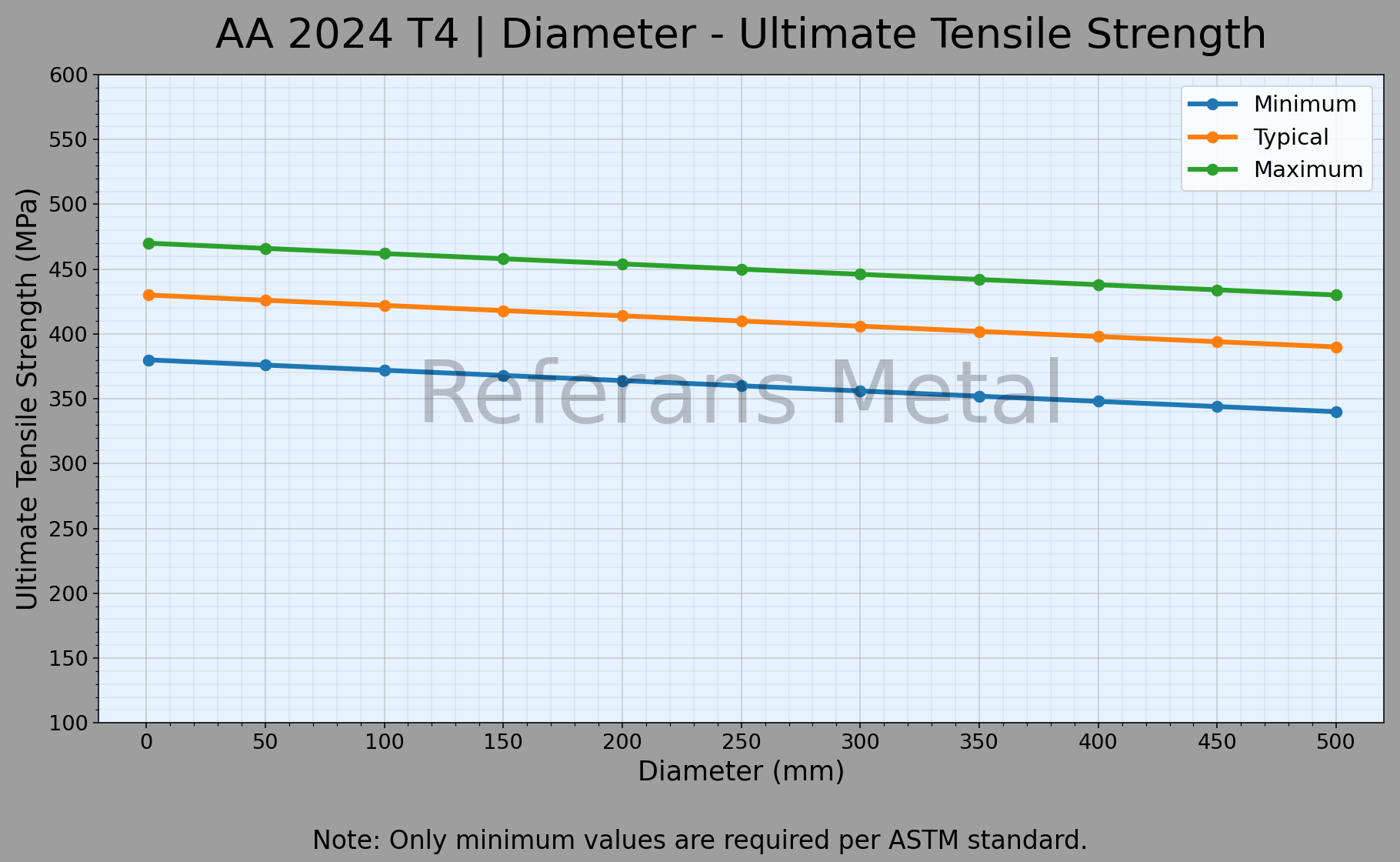

| 2024 T4 Diameter – Ultimate Tensile Strength Graph |

|

The 2024-T4 aluminum alloy belongs to the wrought Al-Cu-Mg alloy group and is primarily developed for applications requiring high strength and superior fatigue resistance. The T4 temper is achieved through solution heat treatment followed by natural aging, providing a favorable balance between strength and formability. In terms of mechanical properties, 2024-T4 exhibits significantly higher strength than 6061-T6, while remaining less strong but more ductile than 7075-T6. When compared to 2017-T451, it offers similar strength levels, with generally superior fatigue performance.

.png) From a corrosion resistance standpoint, 2024-T4 demonstrates limited performance due to its relatively high copper content. As a result, it falls behind magnesium-silicon based alloys such as 6061-T6 and typically requires surface protection in most applications. In terms of coatability, the alloy is compatible with anodizing, painting, and other coating processes; notably, when supplied in Alclad (pure aluminum-clad) sheet form, its corrosion resistance is significantly enhanced. Compared to 7075-T6, the post-coating corrosion behavior of 2024-T4 is considered more uniform and predictable.

From a corrosion resistance standpoint, 2024-T4 demonstrates limited performance due to its relatively high copper content. As a result, it falls behind magnesium-silicon based alloys such as 6061-T6 and typically requires surface protection in most applications. In terms of coatability, the alloy is compatible with anodizing, painting, and other coating processes; notably, when supplied in Alclad (pure aluminum-clad) sheet form, its corrosion resistance is significantly enhanced. Compared to 7075-T6, the post-coating corrosion behavior of 2024-T4 is considered more uniform and predictable.

Regarding machinability, 2024-T4 provides good performance in machining operations and enables the production of components with tight dimensional tolerances. It delivers good surface finish in CNC milling and turning processes, offering better machinability than 6061-T6 and performance comparable to 7075-T6. Its bending capability is relatively favorable due to the ductility associated with the T4 temper, allowing smaller bend radii compared to high-strength T6-tempered alloys. In terms of vibration response, the alloy exhibits stable behavior under dynamic loading conditions, supported by its high stiffness and good fatigue resistance.

Weldability of the 2024-T4 aluminum alloy is generally considered limited. The elevated copper content increases the risk of hot cracking and degradation of mechanical properties in the weld zone; therefore, alloys such as 6061-T6 are often preferred for welded structures. Consequently, 2024-T4 is commonly joined using riveting and other mechanical fastening methods. It is widely used in the aerospace and defense industries, as well as in automotive, space, and structural engineering sectors, particularly for aircraft fuselage panels, wing components, fasteners, and parts subjected to high fatigue loads.

MATERIAL COMPOSITION STANDARDS

2024 T4 is available in the following standards:

• 2024 T4 Cold-Drawn Round Bar; AMS 4120, AMS QQ-A-225/6, ASTM B211

• 2024 T4 Cold-Drawn Bar; AMS 4120, AMS QQ-A-225/6, ASTM B211

• 2024 T4 Cold-Drawn Wire; AMS 4120, AMS QQ-A-225/6, ASTM B211

• 2024 T4 Extruded Round Bar; AMS QQ-A-200/3, ASTM B221

• 2024 T4 Alclad Sheet; AMS QQ-A-250/5, AMS 4279, ASTM B209, EN 2703

Characteristic Properties of 2024 T4:

- Strength: High

- Machinability: Good

- Weldability: Moderate (Spot welding is preferred)

- Formability: Poor

- Corrosion Resistance: Moderate

- Heat Treatment: Yes

Common Applications of 2024 T4:

Used in aircraft fuselage connection components,

Aircraft engine covers,

Also used in computer components.

STOCK

2024 T4 is supplied in sheet/plate, rod/bar, and sheet form.

- Sheet/Plate

- Sheet

- Rod/Bar

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| over 0,25 up to & incl. 6,35 mm | 265 MPa | 427 MPa | 12% - 15% |

| over 6,35 up to & incl. 12,7 mm | 265 MPa | 427 MPa | 10% |

| over 12,7 up to & incl. 25,43 mm | 260 MPa | 420 MPa | ≥8% |

| over 25,4 up to & incl. 50,8 mm | 260 MPa | 415 MPa | ≥6% - 7% |

| over 50,8 up to & incl. 76,2 mm | 260 MPa | 400 MPa | ≥4% |

Weight Calculator

Weight Calculator