冷拔 铝圆棒

冷拔 圆管

7075

Cold Drawn/Finished (CF) / AlZn5.5MgCu (Soğuk Çekim) / 7075 / T73511

| 化学性质 | % 值 |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Aluminium (Al) | Balance |

| 物理特性 | 值 |

| Density | 2.81 g/cm³ |

| Melting Point | 477°C |

| Thermal Expansion | 23 µm/m.°C |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 155 W/m.K |

| Electrical Resistivity | %33 IACS |

| 机械性能 | 值 |

| Proof Strength | 420 MPa |

| Yield Strength | 513 MPa |

| Shear Strength | 303 MPa |

| Elongation A50 mm | %8 |

| Hardness | 135 HB |

7075 T73511 aluminum alloy is characterized by a special heat treatment condition that balances high strength with improved corrosion resistance and enhanced formability. It is commonly chosen for demanding sectors such as aerospace, defense, automotive, and industrial machinery manufacturing, where both performance and durability are paramount. Compared to the T6 condition, T73511 offers a more balanced strength-corrosion resistance profile and contributes to an extended fatigue life for critical components.

The alloy’s surface is suitable for anodizing, allowing for improved aesthetics and enhanced corrosion resistance. While the 7075 series can be challenging to weld, certain conditions, proper filler materials, and controlled heat inputs can make welding feasible. Despite its inherent hardness, 7075 T73511 can be bent to a limited extent by applying preheating and employing specialized forming techniques, enabling the production of complex profiles and parts.

In high-vibration environments, the alloy’s balanced properties and excellent fatigue resistance ensure that components maintain their integrity and reliability over time. Its improved corrosion resistance is particularly beneficial in marine, coastal, and industrial conditions, extending product service life and reducing maintenance costs, thereby enhancing long-term system efficiency.

Advantages of 7075 T73511 include its high strength, enhanced corrosion resistance, good fatigue endurance, anodizing capability, and suitability for use in vibration-prone conditions. Its drawbacks include somewhat limited weldability, the need for careful machining and forming procedures, and increased tooling wear due to its hardness. Altogether, these characteristics make 7075 T73511 an attractive choice where high performance, long service life, and reliability are essential.

Extrusion Rod, Flat Bar, Pipe, Profile as; 7075 T73511, AMS QQ-A-200/11,

AMS 4167, ASTM B221, EN 2127, EN 2632, EN 2315

BS 2 L160

Choosing Factors for 7075 T73511:

- Strength: Fair

- Machining: Moderate

- Weldability: Weak

- Formability: Low

- Corrosion Resistance: Significant

- Heat Treating:Yes

TEMPER TYPES

BS L160 7075 is supplied in the following heat treatment types:

- T73510

- T73511

For high precision automotive parts,

Aircraft engines

As connection apparatus in aircrafts.

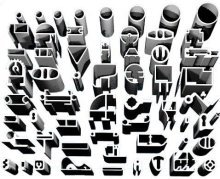

- Rod / Round Bar / Flat Bar

- Tube / Extrusions / Profile

计算 重量计算

计算 重量计算