Cold Drawn Round Bar

Cold Drawn Tube

2124

Cold Drawn/Finished (CF) / AlCu4Mg1 (Soğuk Çekim) / 2124 / T6

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,20 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,30 - 0,90 |

| Magnesium (Mg) | 1,20 - 1,80 |

| Copper (Cu) | 3,80 - 4,90 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,30 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.78 g/cm³ |

| Melting Point | 502 °C |

| Thermal Expansion | 21.9 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 145 W/m.K |

| Electrical Resistivity | 38 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 430 MPa |

| Yield Strength | 490 MPa |

| Shear Strength | 280 MPa |

| Elongation A50 mm | 6 % |

| Hardness | 110 HB |

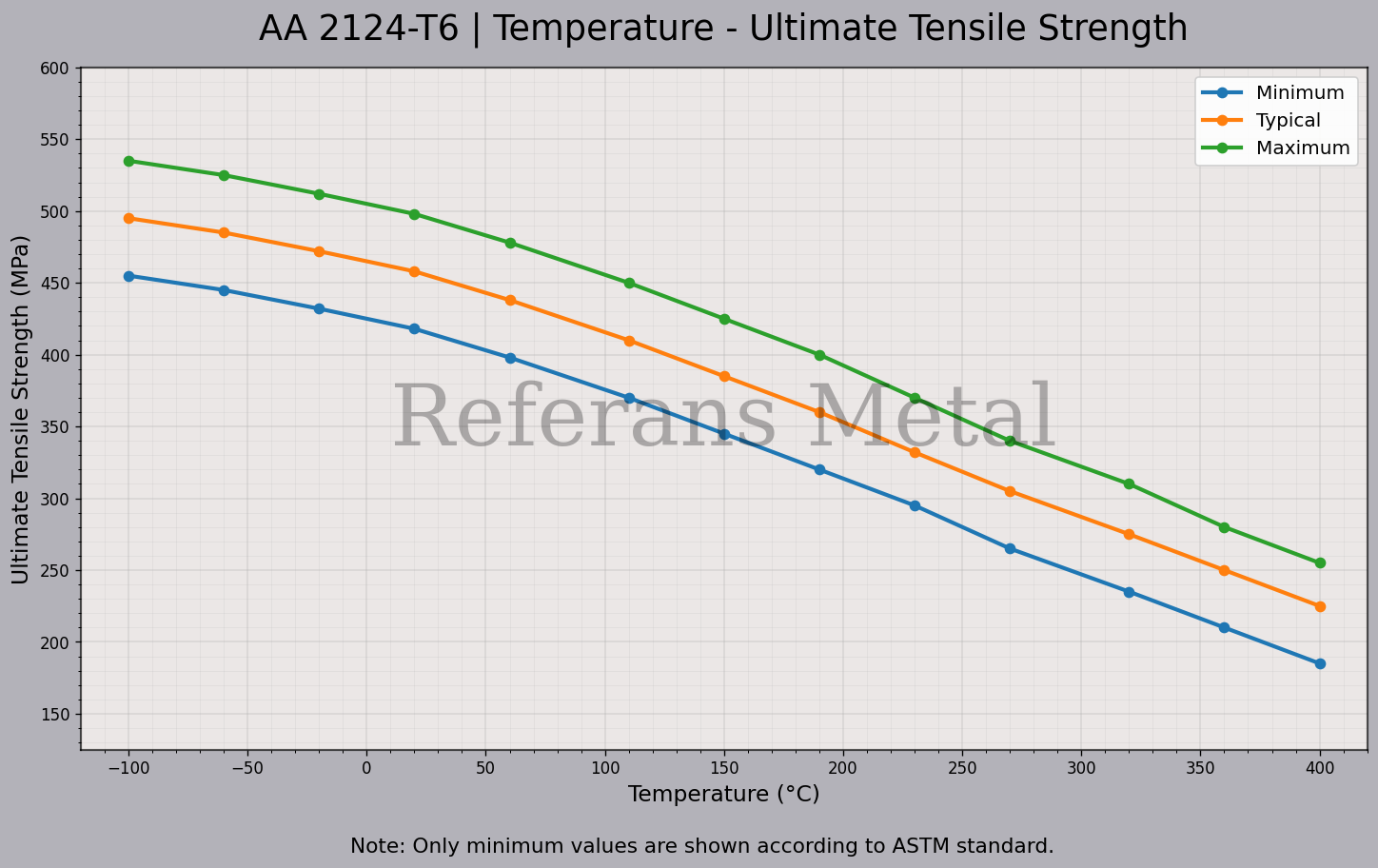

| 2124 T6 Temperature – Ultimate Tensile Strength Graph |

|

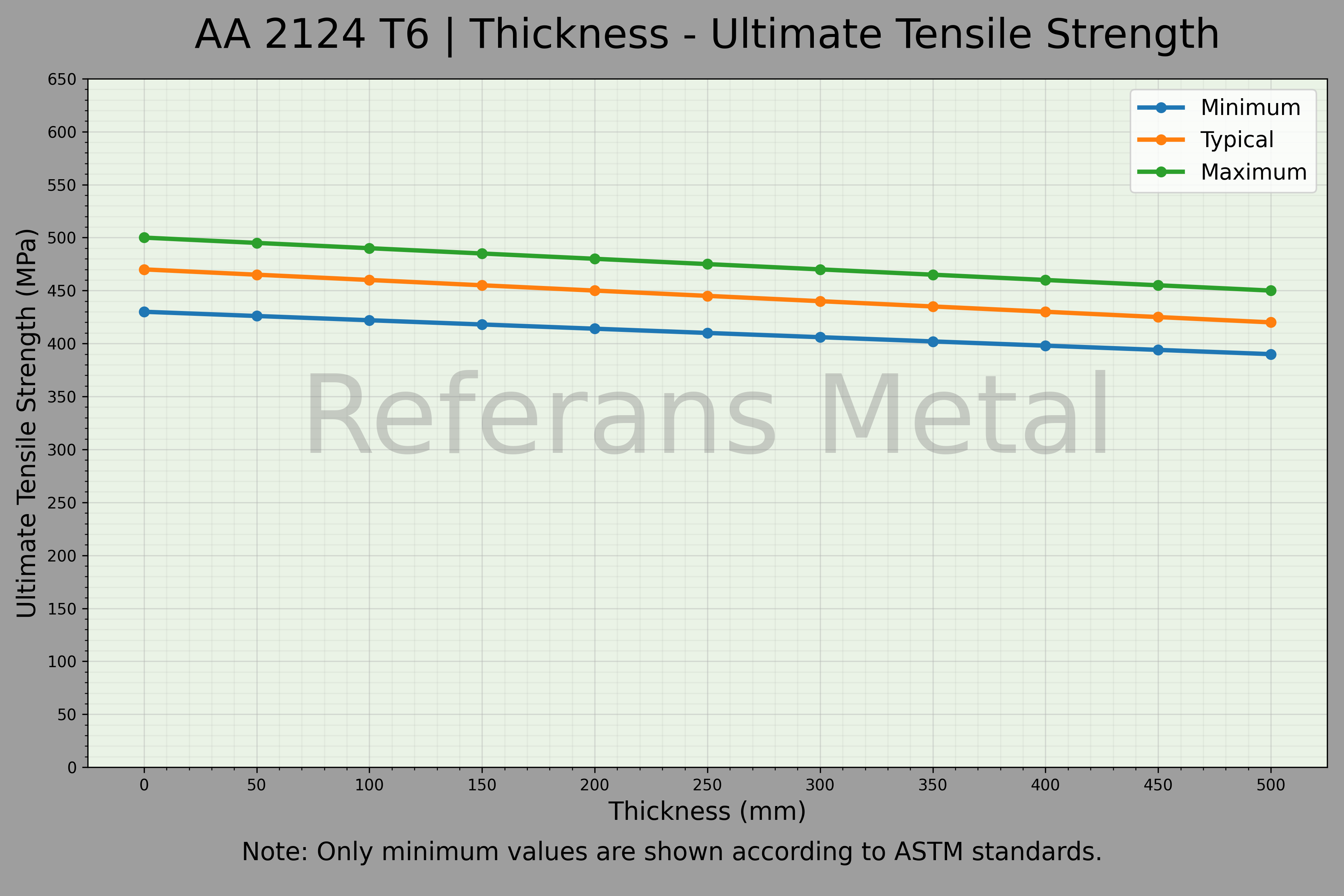

| 2124 T6 Thickness – Ultimate Tensile Strength Graph |

|

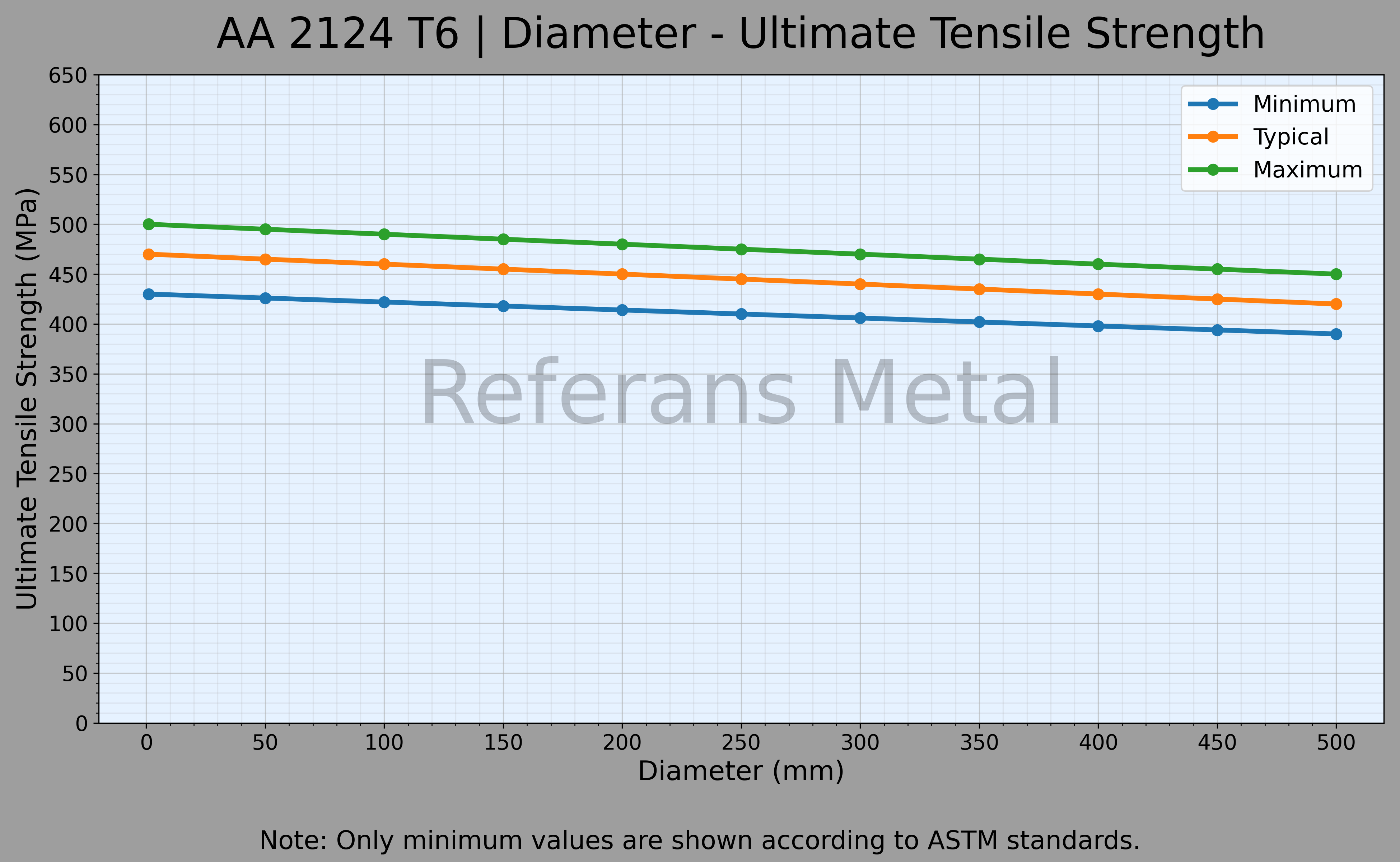

| 2124 T6 Diameter – Ultimate Tensile Strength Graph |

|

Cold-drawn 2124 T6 aluminum alloy is a material distinguished by high strength and excellent fatigue resistance. It is widely used in structural parts in the aerospace industry, automotive components requiring high durability, and heavy industrial equipment. This alloy is suitable for anodizing, which increases surface hardness and wear resistance, providing long-lasting use and an aesthetic surface appearance. However, due to its copper content, corrosion resistance is moderate; therefore, additional protective coatings are recommended for outdoor and humid environments.

Due to limited weldability, mechanical joining methods such as screwing or riveting are generally preferred. The cold-drawing process enhances formability, making the alloy suitable for complex shapes; this also makes it a bendable and flexible material. Additionally, thanks to its durable performance in high-vibration environments, it is ideal for moving parts and applications where fatigue resistance is critical. The advantages of 2124 T6 include high strength, anodizing compatibility, and machinability, while its disadvantages are limited weldability and moderate corrosion resistance. With these properties, it stands out as a reliable material for projects requiring durability and strength.

MATERIAL COMPOSITION STANDARDS

2124 T6 can be produced according to the following standards:

• 2124 T6 Cold Drawn Round Bar; ASTM B211, AMS 4339, UNS A92124

• 2124 T6 Cold Drawn Tube; AMS 4087, WW-T-700/3, ASTM B211, UNS A92124

Characteristic Properties of 2124 T6:

- Strength: High

- Machinability: Above Average

- Weldability: Moderate (Spot welding is preferred)

- Formability: Low

- Corrosion Resistance: Poor

- Heat Treatable: Yes

Well-Known Applications of 2124 T6:

Military vehicles,

Project-based aerospace applications,

Applications requiring high transverse rupture strength.

STOCK

2124 T6 is supplied in rod/flat bar and tube/profile forms.

- Rod / Flat Bar

- Tube / Profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 38.1 up to & incl. 50.8 | 393 MPa | 455 MPa | %5 |

| Over 50,8 up to & incl. 76,2 | 393 MPa | 448 MPa | %4 |

| Over 76,2 up to & incl. 101,6 | 386 MPa | 448 MPa | %4 |

| Over 101,6 up to & incl. 127 | 379 MPa | 441 MPa | %4 |

| Over 127 up to & incl. 152,4 | 372 MPa | 434 MPa | %4 |

Weight Calculator

Weight Calculator