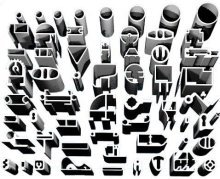

Platos

Hojas

Barras Circulares

Tubos / Extrusion / Perfil

5454

AMS QQ-A-250/10 / AlMg3Mn / 5454 / O

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,25 |

| Chromium (Cr) | 0,05 - 0,20 |

| Manganese (Mn) | 0,50 - 1,00 |

| Magnesium (Mg) | 2,40 - 3,00 |

| Copper (Cu) | 0,0 - 0,10 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,40 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.68 g/cm³ |

| Melting Point | 602 °C |

| Thermal Expansion | 21.9 µm/m-.°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | %34 IACS |

| Mechanical Properties | Value |

| Proof Strength | 117 MPa |

| Yield Strength | 248 MPa |

| Shear Strength | 160 MPa |

| Elongation A50 mm | 17% |

| Hardness | 62 HB |

5454 O aluminum alloy is known for its high corrosion resistance, excellent weldability, and moderate strength. With its magnesium content, this alloy offers enhanced durability, making it particularly suitable for chemical and marine environments. The O temper indicates that the material is annealed, meaning it has a soft and flexible structure. This feature provides significant advantages in terms of formability and workability.

5454 O is commonly used in applications such as chemical storage tanks, pressure vessels, marine vessels, ship hulls, and fuel tanks in the automotive industry, where it needs to withstand harsh conditions. It is highly suitable for anodizing, forming a smooth oxide layer that enhances corrosion resistance and provides an attractive finish. Regarding weldability, the alloy performs exceptionally well and can be easily joined using standard methods like MIG and TIG welding, maintaining much of its structural integrity after welding.

In terms of bending and forming, 5454 O aluminum alloy is ideal for creating complex shapes due to its soft temper. It does not tend to crack during forming processes, making it an excellent choice for projects requiring precision design. Its suitability for high-vibration environments is notable due to its fatigue resistance and mechanical stability. These properties make it a reliable material for structures and equipment exposed to dynamic loads.

The corrosion resistance of 5454 O is one of its standout features. It demonstrates excellent durability in corrosive environments such as saltwater, humid conditions, and exposure to chemicals. However, it may have limited performance in applications requiring higher strength. Advantages include high corrosion resistance, excellent weldability, and outstanding formability, while its disadvantages include limited load-bearing capacity. These features make 5454 O an ideal material for projects requiring lightweight, durability, and reliability.

Sheets per; 5454 O, ISO AlMg3Mn, DIN AlMg2.7Mn, WNR 3.3537, UNS A95454, ASTM B209, AMS QQ-A-250/10

Extruded Round/Flat Bar and Tubes per; 5454 O, ISO AlMg3Mn, DIN AlMg2.7Mn, WNR 3.3537, UNS A95454, ASTM B221, AMS QQ-A-200/6

Choosing Factors for 5454 O

- Strength: Average

- Machining: Decent

- Weldability: Okay

- Formability: Excellent

- Corrosion Resistance: Very good

- Heat Treating: None

Some Well-Known Applications for 5454 O

In the construction of truck bodies,

In chemical process plants,

It is also used in cryogenic applications.

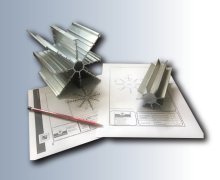

SUPPLIED FORMS

- Sheet

- Round/Flat Bar

- Tube/Profile

Calculador de Peso

Calculador de Peso